Here at Indelac Controls, we strive towards innovation and encourage new ideas so we can continue to offer reliable actuator products to fit the electric actuator needs of our customers and the market. In this effort, Indelac has designed a submersible enclosure option compatible with our popular M Series and SNS4-15 Series Electric Actuators. The M Series electric actuator is ideal for valve automation with a standard ISO mounting configuration, output torque options up to 1500in-lbs, 5 motor voltage options, open/closed or modulating control options, and an optional integrated battery backup system for fail-safe operation (SNS-Series Only).

The project began when one of ICI’s customer’s (a large US automotive manufacturer) wanted to reduce their impact on the environment by incorporating green/eco-friendly designs into their facilities. One of their building projects set out to utilize rainwater collection to satisfy a factory’s non-potable water requirements by using the rainwater collected from the factory roof to accomplish tasks like flushing toilets. When the auto manufacturer approached Indelac, they were looking for a way to automate the flow of water for their rainwater collection and storage system for their manufacturing facility with a submersible electric actuator.

At that time Indelac did not have a submersible actuator solution but had NEMA 4 & 4X enclosures that could be easily modified for the job. The Indelac team went to work! After reviewing the application requirements and specifications with our client ICI agreed to take on the challenge. Our design engineers set out to develop and test a submersible enclosure to help our client achieve their green initiatives using Indelac electric actuators. Keep reading below for a summary of the test performed here at Indelac Controls.

Electric Actuator Submerged in a 6-foot Column of Water

This test started at the end of the summer 2013 at Indelac facility, in Northern Kentucky, behind the 15,000 square foot factory. One of Indelac electric actuator meeting NEMA 6P specifications was immersed in a column of water made of 2 barrels welded together (see picture on the left).

The actuator was equipped with a timer to automatically actuate the device every 90 seconds.

After several months in the water, the column of water even froze into ice over the winter but the actuator was still functioning, reaching an outstanding 101,000 cycles in December 2013.

The actuator was equipped with a timer to automatically actuate the submersible electric actuator every 90 seconds, 24 hours a day, 7 days a week. After several months under water, the column of water even began to freeze and thaw over the winter! No problem for the Indelac electric actuator. Under the ice and water, in below freezing temperatures the actuator was functioning normally, reaching an outstanding 100,001 cycles in December 2013.

Breaking the Ice and Inspection of the Actuator

Once 100,000+ cycles were reached it was time to break through the ice and evaluate the electric actuator, as can be seen on this next picture below:

The electric actuator was disconnected from the power and taken inside the factory where the cover was removed. Upon cover removal and inspection there were no signs of water ingress or corrosion present.

Next, the technician reconnected the power supply to the electric actuator at the bench. Once connected, the power was turned back on, and the unit was cycled open and close successfully.

After several months immersed under 6 feet of water, the actuator didn’t miss a beat and functioned perfectly, was corrosion free with exception of the rust from the inside of the steel drums on the exterior of the enclosure.

Each submersible electric actuator is equipped with a heater as standard equipment, however, the heater inside the actuator was not wired during this experiment.

Click Below to Watch: Submersible Electric Actuator Test

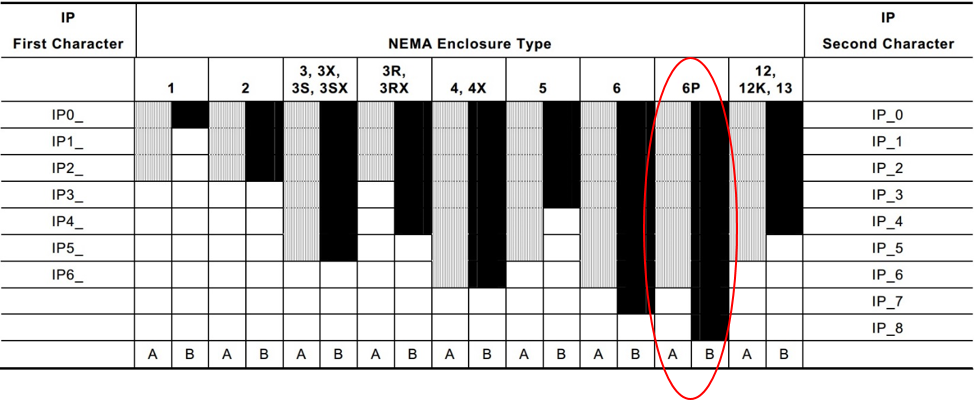

Additional Resources: NEMA 6/6P & IP68 Enclosure Ratings

Below are some tables detailing the level of protection that NEMA 6/6P offers compare to other NEMA ratings. As can be seen, a NEMA 6P electric actuator can be used not only under water for a prolonged submersion. The NEMA 6/6P rating can also be used in an environment with corrosive agents. As one of the most versatile electric actuator enclosure options NEMA 6P is built for extreme conditions for both indoor and outdoor applications offering a high degree of protection for the electronics inside.

Please see the following diagrams:

Comparison of Specific Applications of Enclosures for Indoor Nonhazardous Locations [From NEMA 250-2003]

![Comparison of Specific Applications of Enclosures for Indoor Nonhazardous Locations [From NEMA 250-2003]](https://www.indelac.com/hs-fs/hub/149978/file-2641319994.jpg?width=700&name=file-2641319994.jpg)

Comparison of Specific Applications of Enclosures for Outdoor Nonhazardous Locations [From NEMA 250-2003]

![Comparison of Specific Applications of Enclosures for Outdoor Nonhazardous Locations [From NEMA 250-2003]](https://www.indelac.com/hs-fs/hub/149978/file-2623732611.jpg?width=700&name=file-2623732611.jpg) * These enclosures may be ventilated.** External operating mechanisms are not required to be operable when the enclosure is ice covered.*** External operating mechanisms are operable when the enclosure is ice covered

* These enclosures may be ventilated.** External operating mechanisms are not required to be operable when the enclosure is ice covered.*** External operating mechanisms are operable when the enclosure is ice covered

Finally, this last table shows how NEMA 6P fully meets IP68 standards.

.png?width=459&name=conversion_of_nema_enclosure_type_ratings_to_iec_60529_enclosure_classification_designations_(ip).png)